The most important glove standards at a glance

Hand protection is part of personal protective equipment (PPE). All protective gloves are subject to various standards and must be tested for different factors. Gloves can also be categorised into three different PPE categories.

Whether you are working on a construction site or in a laboratory, your hands should be protected from the known risks of your workplace. Our specialist advisors will be happy to help you choose the right work gloves for your application. Simply contact us via our website chat, by email or by phone!

PPE category I - Low risks

All gloves that protect against low mechanical risks are assigned to the lowest category. They can be worn for work where low risks are expected. Gardening gloves or cotton gloves, for example, can be assigned to this category.

PPE category II - medium risks

Gloves assigned to category 2 protect against medium risks and are worn for work where curable damage should be expected. These include assembly gloves, cut protection gloves, welding gloves and cold protection gloves.

PPE category III - High risks

Category 3 gloves must be worn for work where irreversible or even fatal hazards are to be expected. This includes chemical protective gloves, for example.

The glove DIN standards at a glance

There are numerous DIN standards for which gloves can or must be tested. Below is an overview of the most important standards for work gloves.

DIN EN 21420:2020-06 - General requirements and test methods

Specifies the relevant test methods to be used for all protective gloves and the general requirements for design principles, glove manufacture, resistance of the glove material to water penetration, harmlessness, comfort and performance as well as the labelling to be carried out by the manufacturer and the information to be provided by the manufacturer.

DIN EN 12477 Type A + B - Standard for welding gloves

The DIN EN 12477 standard is a combination or merger of the two standards DIN EN 388 and DIN EN 407. Accordingly, protective gloves for welders should protect the hands and wrists from the following hazards:

- Contact heat

- Mechanical risks

- Brief contact with moderate exposure to flames

- Small amounts of molten metal

- UV radiation & electric arc

DIN EN 388 - Standard for mechanical risks

DIN EN 388 is the standard for gloves for protection against mechanical risks. The associated pictogram for the standard is the hammer symbol. The performance in the various areas of protection is specified in levels.

DIN EN 511 - Standard for protection against the cold

Gloves certified to DIN EN 511 are designed to protect the wearer against convective cold (penetrating cold), contact cold and water permeability. Cold protection gloves are also categorised into different performance levels - these are indicated by a number from 1 to 4 under the pictogram.

DIN EN 407 - Standard for thermal risks

Gloves certified to DIN EN 407 are designed to protect against contact heat, radiant heat and small amounts of molten metal. The performance levels are also indicated below the pictogram.

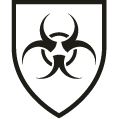

DIN EN 374 - Protects against hazardous chemicals and micro-organisms

DIN EN 374-1 (Part 1): Terminology and performance requirements for chemical risks

The DIN EN 374 standard is intended to provide the wearer with protection against chemicals and micro-organisms such as bacteria, fungi and viruses. For example, chemical protective gloves are tested for protection against 18 different chemicals. The pictogram associated with the standard is the Erlenmeyer flask. The protective performance of the glove is further differentiated into type A, type B and type C.

- Type A: Resistant to at least 6 test chemicals for at least 30 minutes

- Type B: Resistant to at least 3 test chemicals for at least 30 minutes

- Type C: Resistant to at least 1 test chemical for at least 10 minutes

DIN EN 374-2 (Part 2): Determination of resistance to penetration

Although protective gloves labelled with the beaker are liquid-tight, they do not provide complete protection against chemical risks. The beaker pictogram is rarely used on current glove models. As a rule, it is replaced by the Erlenmeyer flask pictogram in combination with the type C designation.

DIN EN 374-5 (Part 5): Terminology and performance requirements for risks from micro-organisms

Gloves labelled with the virus pictogram primarily offer protection against dangerous microorganisms such as viruses, bacteria and fungi. Gloves complying with this standard must not leak under any circumstances. Gloves that have passed the test for full protection against viruses are clearly labelled with the word "virus" in the user instructions. If, on the other hand, protection against viruses has not been tested, the warning "Not tested against viruses" must be visible to the user.